How manufacturing is using Mixed Reality to solve everyday challenges within their business.

The UK Government department for business and trade reports that from 2019 to 2024, it is expected there will be a 78.3% growth rate for spending on AR and XR in the UK. Growth is predicted to reach £62.5 billion by 2030, reflecting increasing demand and confidence in these technologies, signalling a remarkable shift in industry dynamics.

Entertainment and gaming are usually the main industries associated with Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (XR). However, these immersive technologies are increasingly making their mark in other unsuspecting industries, revolutionising how businesses operate and innovate.

For example, in the world of manufacturing Augmented Reality Technology is proving to be a game-changer. By overlaying digital information onto the physical world, AR experiences are enhancing accuracy and efficiency in every day complex procedures and processes. Similarly, these solutions are gaining popularity within enterprise settings too, supporting training and development alongside other practical use cases.

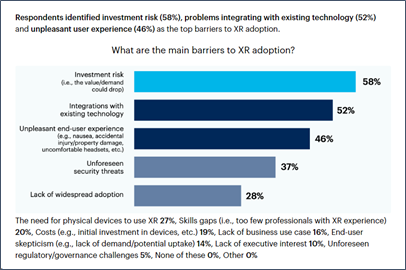

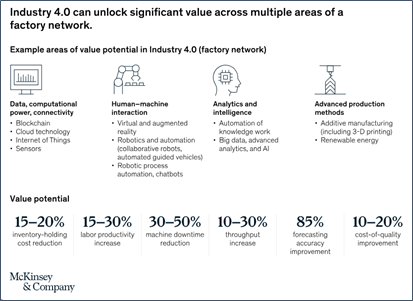

Despite the clear benefits, many businesses hesitate to embrace technology innovation because of perceived barriers to entry. According to a Gartner survey, investment risk, integration challenges, and concerns about user experience top the list of concerns (see Fig.1). However, McKinsey & Co (see Fig.2) suggest that the use of Industry 4.0 technologies including AR holds substantial value across various aspects of a business’s operation.

Fig.1

Fig.2

McKinsey’s findings highlight significant potential, including increased labour productivity, minimised machine downtime and enhanced throughput. These advantages underscore the game changing impact of AR technology on manufacturing processes.

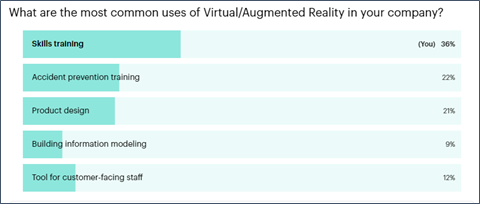

Companies already using XR for business say that the most common use case for the tech is training, followed by product design (See fig.3). However, this research doesn’t drill down into specific industries, where we are seeing varying examples of where AR is being used to support everyday tasks.

Extended Reality use cases for manufacturing:

- Maintenance and repairs – Part and parcel of everyday operations within a factory. To keep production moving, businesses must deal with maintenance and repairs quickly and efficiently. XR gives step-by-step work instruction that is easy to follow and always accurate, virtually hand holding your frontline workforce every step of the way.

- Productivity improvements – Giving employees the data and guidance they need to perform tasks in real time. Meaning they are more productive, making less mistakes and completing tasks with more accuracy than ever before.

- Training and upskilling – Training is vital when dealing with complex equipment and heavy machinery. Manufacturers are using XR technology to give employees extensive training more regularly in a risk-free virtual environment.

- Collaboration – Your team can collaborate with each other no matter where they are in the world. Digital Twin technology allows technicians to use a virtual environment to work together on projects and tasks.

Fig. 3

Businesses can achieve greater efficiencies and growth by embracing transformative tools and overcoming initial barriers to entry. Industries are increasingly realising XR’s great potential and using it to shape the future of their business.

6 business benefits of XR for Manufacturing:

- Significantly reduce the time it takes to train new starters

- Digitalise paper-based processes and procedures

- Improve knowledge transfer, bridging the knowledge gap

- Ensure safer working practices

- Improve productivity of frontline workforce

- Reduce risk of mistakes and margin for error with step-by-step instruction

Overall, XR holds immense potential for transforming manufacturing operations, driving efficiency, quality, safety, and innovation while empowering employees. As AR continues to evolve and mature, its role in reshaping the future of manufacturing will become increasingly apparent.

Mixed Reality from CAD-IT

CAD-IT’s Industrial Mixed Reality solution has been created with customers in mind. In fact, we worked closely with them whilst in developing it to ensure we address their everyday challenges. A solution that integrates seamlessly with their existing content authoring systems. Remains on-premise for increase security and peace of mind, and requires no coding experience to get started.

Talk to a team member to learn how you can use XR and start benefiting from the technology right away.

Email info@cadituk.com or visit our website www.cadituk.com to discover the exciting uses of XR

References:

Manufacturing | Automotive & Assembly | McKinsey & Company

Augmented reality and virtual reality – great.gov.uk international

Extended Reality (XR) in the Enterprise | Gartner Peer Community