By Helitha Rupasinghe

If you’ve ever been involved in manufacturing, engineering, or any product development process, chances are you’ve come across the term “Bill of Materials” or BOM. The Bill of Materials is a crucial document that serves as the foundation for any successful manufacturing project. In this blog post, we will demystify the concept of Bill of Materials, explore its purpose, components, and how it contributes to the overall production process.

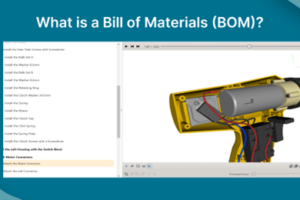

- What is a Bill of Materials (BOM)?

A bill of materials is the complete list of all the components, sub-components, raw materials, assemblies, and quantities required to manufacture a product. A well-structured BOM typically includes the following components like Part Number: Description, Quantity, Unit of Measure, Manufacturer and supplier information and Cost. It acts as a roadmap, providing a detailed breakdown of what is needed and how to assemble the final product. The BOM serves as a bridge between the design and production stages, ensuring accurate material sourcing, cost estimation, and efficient manufacturing.

- Types of Bills of Materials

There are different types of BOM’s that serve various purposes depending on the stage of the product development cycle. Some common types include:

- Engineering BOM (EBOM): This BOM is created during the product design phase and focuses on the technical aspects, including detailed specifications and materials required.

- Manufacturing BOM (MBOM): The MBOM is derived from the EBOM and includes all the components needed for production, along with specific manufacturing instructions, process parameters and routing information.

- Service BOM (SBOM): The SBOM lists the components necessary for product maintenance, repair, or replacement. It ensures accurate spare parts inventory management and facilitates efficient after-sales service.

- Benefits of a Bill of Materials

Implementing a well-structured Bill of Materials offers several advantages:

- Improved Planning: The BOM provides a clear roadmap for product development, enabling efficient planning, scheduling, and resource allocation.

- Accurate Cost Estimation: With a detailed BOM, manufacturers can accurately estimate the cost of a production, aiding in budgeting and pricing decisions.

- Streamlined Procurement: The BOM helps identify and source the required materials efficiently, reducing delays and ensuring timely production.

- Enhanced Collaboration: The BOM serves as a common reference point for different teams involved in the production process, fostering effective communication and collaboration.

- Quality Control: A comprehensive BOM assists in quality control by ensuring the correct components are used and facilitating traceability in case of issues or recalls.

- Best Practices for Creating a Bill of Materials

To optimize the effectiveness of your BOM, consider the following best practices:

- Maintain Consistency: Use Standardized formats and terminology to ensure clarity and consistency throughout the BOM.

- Regular Updates: Keep the BOM up to date as changes occur during the product lifecycle, such as design revisions or component substitutions.

- Version Control: Implement a version control system to track revisions and maintain a track-record of BOM changes.

- Cross-Functional Collaboration: Involve multiple stakeholders, such as design engineers, procurement, and manufacturing teams, to ensure a comprehensive and accurate BOM.

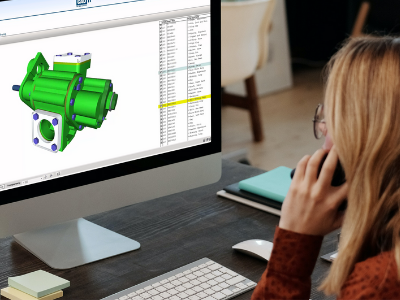

- Utilize BOM management software: Consider using specialized software tools to automate and streamline BOM creation, management, and tracking.

A well-structured and accurate Bill of Materials is an indispensable tool in modern manufacturing and product development processes. By understanding the components, types, and benefits of a BOM, teams can harness its power to streamline production, improve collaboration, and ensure successful product launches. Embrace the power of BOMs and you’ll be well on your way to achieving efficient and cost-effective manufacturing.

For more information on BOM or if you have any questions about how CAD-IT can help your business, contact us at info@cadituk.com