By Ankit Seal

The Industrial Internet of Things (IIoT) has emerged as a transformative force across various sectors, with the Food & Beverage industry being a prime beneficiary. Platforms like Insights Hub (formerly known as Mindsphere) have been instrumental in enabling businesses to harness the power of IIoT, leading to enhanced productivity, operational efficiency, and food safety.

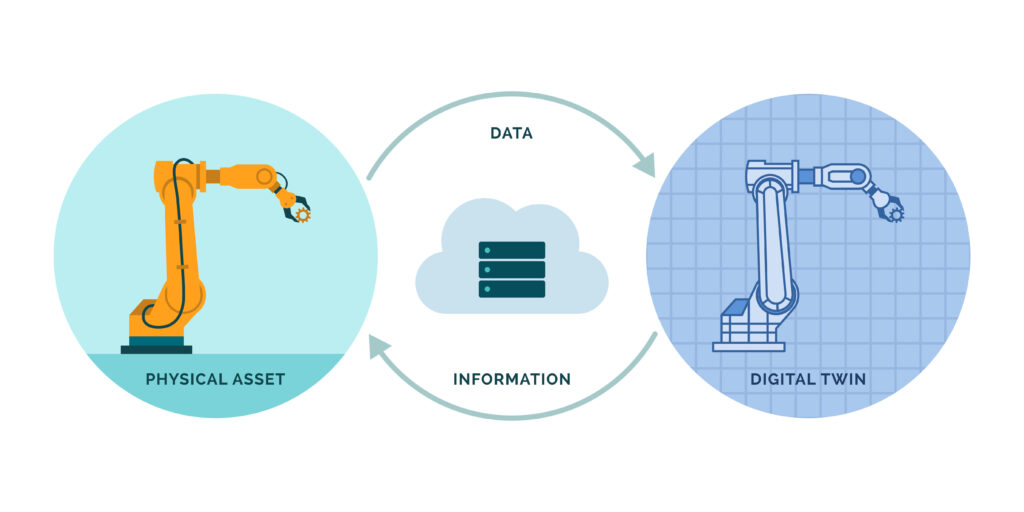

IIoT refers to the integration of connected physical devices with industrial applications. These devices, equipped with sensors, generate data that can be analysed to provide actionable insights. In the Food & Beverage industry, IIoT can monitor production lines, track inventory, and ensure quality control, among other things.

Insights Hub, a cloud-based, open IoT solution, plays a significant role in this field. It enables businesses to tap into the potential of IIoT by connecting products, plants, systems, and machines. With Insights Hub, businesses can collect and analyse vast amounts of data from various sources in real-time. This allows for predictive maintenance, energy data management, and resource optimization, leading to improved operational efficiency and reduced costs.

Key Performance Indicators (KPIs) are crucial in the Food & Beverage industry. They provide measurable values that demonstrate how effectively a company is achieving key business objectives. KPIs may include metrics related to production efficiency, waste reduction, equipment utilization, and food safety compliance, among others. Capturing real-time data using IIoT to monitor these KPIs can significantly impact the functioning of a business, allowing for timely decision-making and continuous improvement.

A real-world example of the transformative power of IIoT and Insights Hub comes from a premium bakery in the UK. The Bakery was facing challenges in scaling up their production to meet growing customer demand due to the handmade nature of their products.

With the support of the Government Innovation programme, The Bakery collaborated with CAD-IT UK to implement a 'Discrete Event Simulation' (DES) pilot. This digital model helped them identify bottlenecks in their production process and determine where their next investment should be, saving them time and money.

By combining the two technologies the Bakery are able to create a true digital twin of the factory. By creating a true digital twin of the factory floor, the Bakery gains valuable insights into the production performance by integrating IIoT data with simulation models. Performing simulation is a business-critical function. Plant Simulation from Insights Hub uses IIoT data gathered from the factory. With functionalities such as bi-directional communication and simulation in a headless mode, businesses can improve their time-to-value for simulation and IIoT solutions with accurate, calibrated simulation models. Some of the key functionalities for the Factory Twin are:

- Information on data transformation and best-fit distribution

- Dedicated UI creating seamless connectivity

- Asynchronous simulation for scheduling, queuing and results management

- Discrete events simulation, visualization, and design threshold

Furthermore, an IIoT solution was developed by CAD-IT UK using the Insights Hub solution. This cloud-based solution supported the company in collecting, managing, and analysing its business data. This case study demonstrates how the combination of IIoT, Insights Hub, and strategic partnerships can transform a business, leading to increased efficiency, growth, and profitability.

In conclusion, the combination of IIoT and solutions like Insights Hub offers immense potential for the Food & Beverage industry. By harnessing the power of these technologies, businesses can improve efficiency, ensure food safety, and stay ahead in the competitive market. For more information on how CAD-IT UK can help your business harness the power of these technologies, contact us at info@cadituk.com.