Mitigating Unplanned Downtime: Harnessing the Power of IIoT

In today's fast-paced manufacturing landscape, the spectre of unplanned downtime looms as a formidable threat to business continuity.

How is unplanned downtime effecting your business?

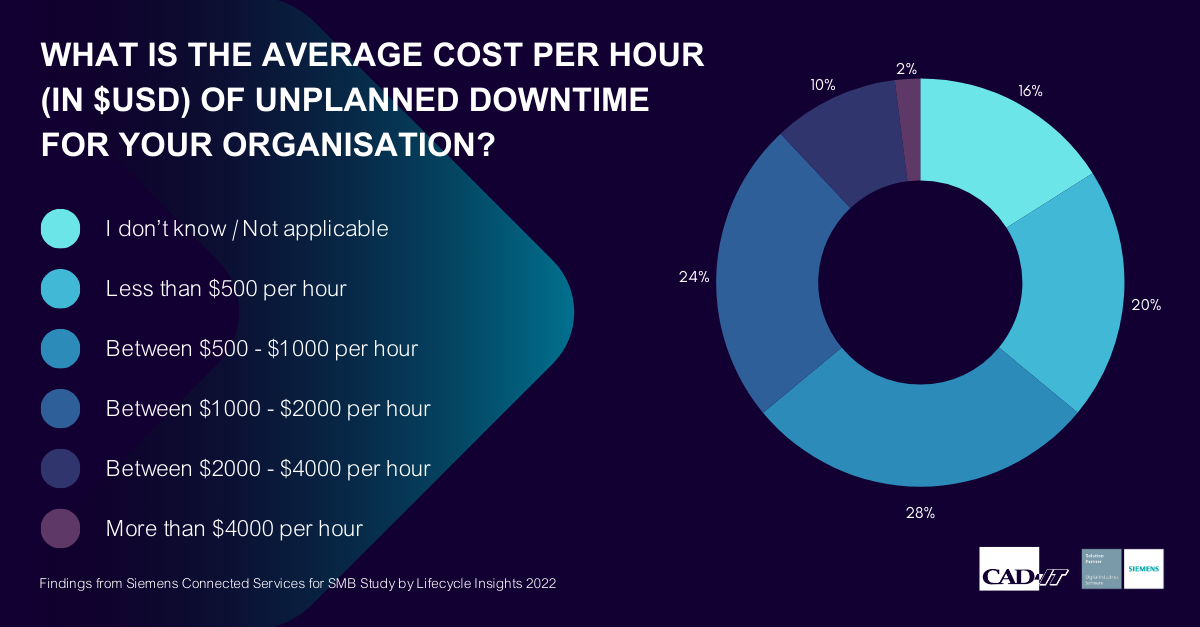

1. Financial Strain: Unplanned downtime hits the bottom line hard, resulting in direct revenue losses and substantial emergency repair costs.

2. Productivity Crunch: Downtime disrupts the production rhythm, leading to decreased productivity and missed targets.

3. Overtime Surge: To compensate for lost production time, companies often resort to overtime work, increasing labour costs and placing additional strain on employees.

4. Supply Chain Disruptions: Delays in deliveries and imbalances in inventory levels due to downtime can trigger a chain reaction of logistical challenges.

5. Customer Dissatisfaction: Unhappy customers, coupled with delayed deliveries, can result in dissatisfaction and a potential loss of valuable clientele.

6. Trust Erosion: The cumulative effect of downtime incidents can erode customer trust in your business's reliability and commitment to service.

Sound familiar?

IIoT: A Game-Changer in Downtime Mitigation

In the quest for operational resilience, the Industrial Internet of Things (IIoT) emerges as a transformative force. This advanced technology empowers businesses to shift from reactive to proactive maintenance strategies, minimising the risk of unplanned downtime.

How exactly can IIoT minimise the risk of unplanned downtime?

1. Real-time Monitoring: IIoT enables continuous monitoring of equipment and processes, providing real-time insights into performance and facilitating early anomaly detection.

2. Predictive Maintenance: Through data analytics, IIoT predicts potential equipment failures, allowing for proactive scheduling of maintenance activities before a breakdown occurs.

3. Condition Monitoring: Continuous tracking of equipment conditions via IIoT ensures timely intervention, preventing unexpected failures and reducing downtime.

4. Data-Driven Insights: Harnessing the vast amounts of data generated by IIoT, businesses gain valuable insights into system performance, aiding in the optimisation of operations.

5. Remote Diagnostics and Troubleshooting: IIoT facilitates remote monitoring, allowing experts to assess equipment health from anywhere, expediting the troubleshooting process and minimising downtime.

6. Asset Performance Management: IIoT-driven Asset Performance Management provides a comprehensive view of asset health, aiding in prioritising maintenance efforts and resource allocation.

As industries evolve, the smart utilisation of IIoT becomes not just a competitive advantage but a necessity. The businesses that harness the power of IIoT are not only safeguarding against unplanned downtime but are also paving the way for a future where operational efficiency is the hallmark of success.

Siemens' Insights Hub, formerly known as Mindsphere, in tandem with CAD-IT's team of adept IIoT advisors and solution engineers, guides businesses through the exploration, implementation, and development of an IIoT roadmap tailored to their specific needs. Feel free to reach out to us today to schedule a complimentary and obligation-free discovery meeting. Explore how IIoT could potentially optimise aspects of your business.